Quality Assurance

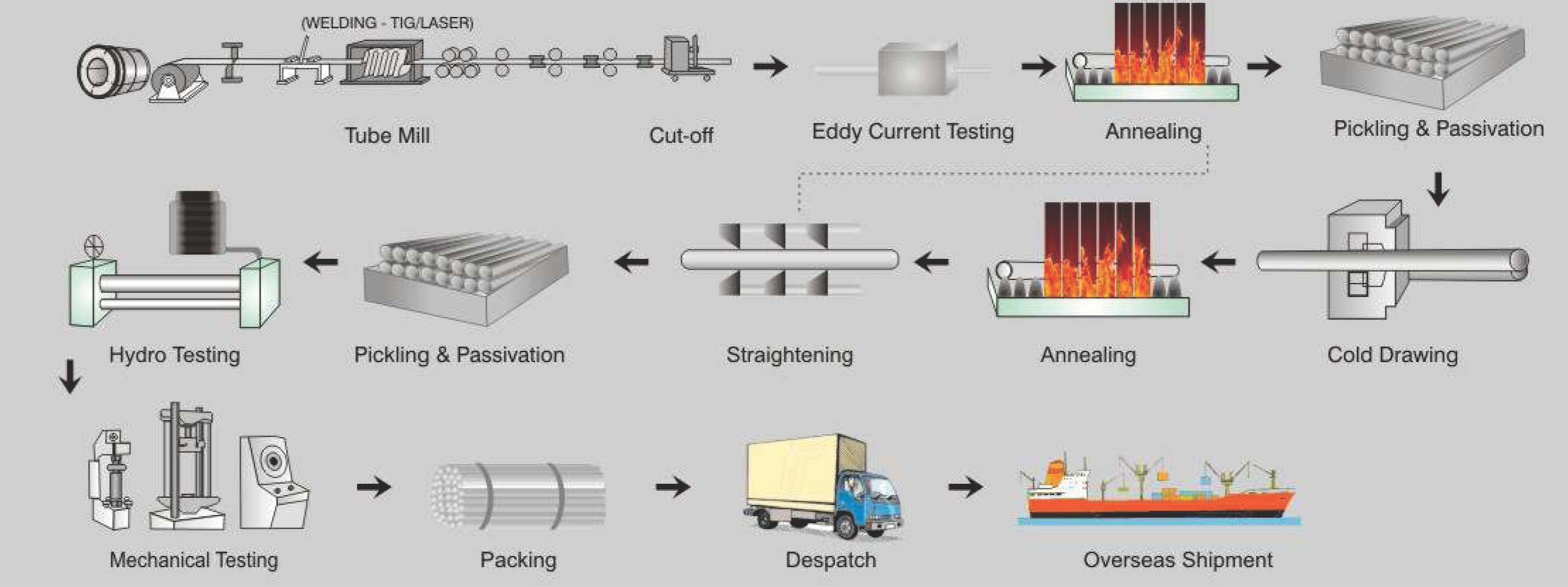

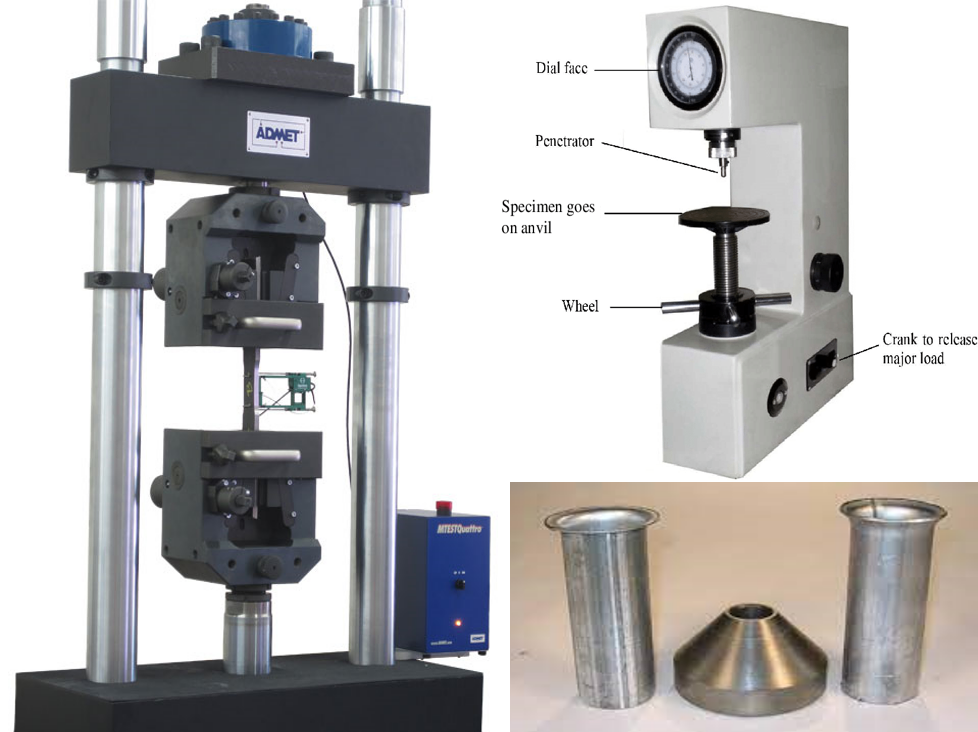

Our quality assurance program is documented in an approved quality assurance manual, which covers all manufacturing, sales and services procedures. We exercise stringent quality control measures for ensuring the accurate dimensions and mechanical properties of our products. Our quality assurance system assures each product to pass through following processes and quality systems:

- -Material Control System

- -Process Control System

- -Machining and Dimensional Control

- -Certification and Supplementary Test

- -Finishing and Marketing

Leveraging on our structured work process, quality is imbibed at all stages of manufacturing. Recognizing our efforts and dedication towards quality products and services.

Stainless Steel Grades

Chemical Composition (in%)

| GRADE | C (Max) | Min (Max) | Si (Max) | P (Max) | S (Max) | Ni | Cr |

|---|---|---|---|---|---|---|---|

| JSLU-SD | 0.15 | - | 0.75 | 0.100 | 0.020 | 0.40-0.75 | 13.25-00.00 |

| J3 | 0.80 | 9.00-10.50 | 0.75 | 0.075 | 0.030 | 2.00-3.00 | 14.00-16.00 |

| J4 | 0.10 | 8.50-10.00 | 0.75 | 0.90 | 0.030 | 1.2Max | 15.00-16.00 |

| JT | 0.08 | 7.5-10.00 | 0.75 | 0.100 | 0.020 | 0.20 | 14.00-00.00 |

| 301 | 0.15 | 2.00 | 1.00 | 0.045 | 0.030 | 6.00-8.00 | 16.00-18.00 |

| 304 | 0.08 | 2.00 | 0.75 | 0.045 | 0.030 | 8.00-10.50 | 18.00-20.00 |

| 304 | 0.08 | 2.00 | 0.75 | 0.045 | 0.030 | 8.00-10.50 | 18.00-20.00 |

| 304 L | 0.03 | 2.00 | 0.75 | 0.045 | 0.030 | 8.00-12.00 | 18.00-20.00 |

| 316 | 0.08 | 2.00 | 0.75 | 0.045 | 0.030 | 10.00-14.00 | 16.00-18.00 |

| 316 L | 0.03 | 2.00 | 0.75 | 0.045 | 0.030 | 10.00-14.00 | 16.00-18.00 |

| 321 | 0.08 | 2.00 | 0.75 | 0.045 | 0.030 | 9.00-12.00 | 17.00-19.00 |

| 409 L | 0.03 | 1.00 | 0.75 | 0.030 | 0.040 | 0.50 Max | 10.50-11.75 |

| 410 S | 0.08 | 1.00 | 1.00 | 0.030 | 0.040 | 0.60 Max | 11.50-13.50 |

| 410 | 0.35 | 1.00 | 1.00 | 0.030 | 0.040 | 0.60 Max | 16.00-18.00 |

| Stainless Steel Grade AISI | Main Characteristics | Typical Application/End products |

|---|---|---|

| 202 | High Cold Work hardening rate, good formability | Water tubings.Watch parts foot rule, industrial Knives, bus body accessories, utensils,Kitchen appliances, Kerosene and gas stove parts. |

| 301 | Attains high strength by being cold worked,while retaining good ductility. | Used in cold Worked condition for springs & wear plates. |

| 304 | Better Welding characteristics with good formability and general | Watch parts,engine gaskets,flexible hoses, foot rule,door hinges,capillary tubings and sinks. |

| 304L | Low carbon content,Weldable and resistance to sensitisation. Good corrosion and oxidation resistance | Hypodermic needles and capillary tubings. |

| 316 | Superior corrosion resistance to sea water and many chemicals and weldable. | Superior corrosion resistance to sea water and many chemicals and weldable. |

| 316 L | Low Carbon content,highly corrosion resistant,weldable and resistant to sensitisation. | Process plant parts particularly in thick sections. |

| 321 | Weldable and resistant to sensitisation.Good corrosion and oxidation resistance. | Heater elements,process plant,furnace parts and high temperature tubes. |

| 409M | Good corrosion and oxidation resistance. | Auto mufflars,catalytic converters and trasformer cases. |

| 409S | Weldable and resistance to scaling.Good corrosion and heat resistance. | Turbine blades.fasteners and fishing tackle. |

| 420 | Superior wearability excellent,corrosion resistanat and hardnable to 500 BHN. | Surgical instruments,Knife blades and valve parts. |

| 430 | Superior corrosion resistance and formable. | Automobile trim and foof processing plants. |

Stainless Steel Tubes & Pipe

We are considered as one of the most popular Stainless-steel Tubes manufacturer and supplier, based in Rohad. Our Stainless-steel Tubes are available in various qualities as per the requirements of the customers. With strong production abilities and technological skills, we are able to provide high tensile Stainless-steel Metal Tubes for various commercial programs.