Plants and Machinery

All of us are familiar with the properties of Stainless Steel, such as high durability, ductility, tensile strength, etc. that make it one of the most reliable materials used in a vast number of industries like the automobile industry, dairy industry, furniture industry, chemical industry and so on.

Now that we know that stainless steel is super useful, we also need to be aware of what goes on inside the industries that manufacture stainless steel in the first place. How do they manufacture it? What are the pieces of machinery that are required? Here are some that we use in our factories :-

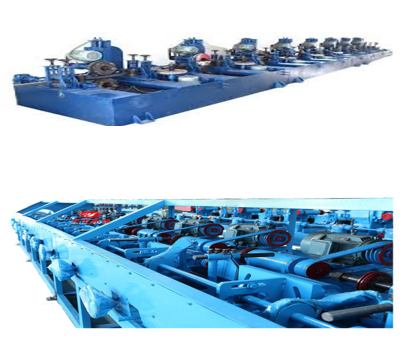

Tube Mill:

We believe that we can not fulfill our pledge of 100% customer satisfaction unless our pieces of machinery are in top shape. This is why our tube mills are exceptionally state-of-the-art. Our pipe mill machine is entirely automated, incredibly advanced, and specially created with the aid of Taiwan technology. We bring to you only the most trustworthy quality Stainless Steel produced from our tube mills. These machines help us produce notably accurate steel and also increase our production capacity exponentially. Additionally, our Tube Mills are equipped with the latest Tungsten Inert Gas (TIG) Welding Tricathode System from Italy.

Moreover, they are equipped with an Infrared Ray Sensor System that helps us make sure that the quality of our welding is up to the mark. They are fully efficient in producing various SS tubing sizes.

Lastly, all our Tube Mills comply with the international standards and are suited for all kinds of industrial requirements.

Roll Sets:

The Roll Sets that we employ are, most probably, the best tubing machine. We have imported our Roll Sets from Taiwan because we do not want to compromise on the quality of our products. They are specially configured to produce the top quality Stainless Steel pipes as well as tubes. Also, they are capable of producing both hollow and round sections.

Furthermore, they are equipped with specialized material Grade Cr12MOV that helps us in manufacturing and shaping the products just the way you desire them to be. Also, they come with SKD61 that is known to assist in welding roll. To be specific, it helps in adjusting the level of heat treatment and that of hardness, and thus, enables us to deliver to you, products with un compromised quality.

Polishing Line:

To keep our promise to bring to our customers only the best and unmatched products and services, we use a polishing line that has been specially imported from Taiwan. Our polishing line is totally automated, super-advanced, and specially created with the help of the latest technology that enables us to give our products enhanced shining and a proper mirror finishing. That’s not all, we also make use of imported polishing materials that allows us to deliver products that are second to none.